-Introducing some of the production and fabrication facilities and testing facilities that ensure high quality and high precision products.-

In order to meet the constantly evolving and demanding requirements of our customers,

we continue to periodically upgrade our facilities to ensure they remain at the cutting edge.

In order to avoid delays in delivery due to equipment problems,

we install two of the same piece of equipment.

-

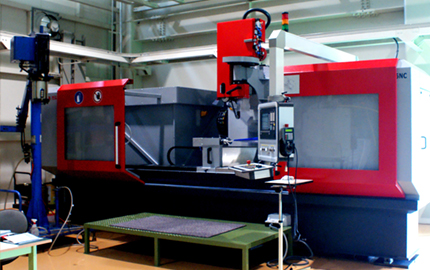

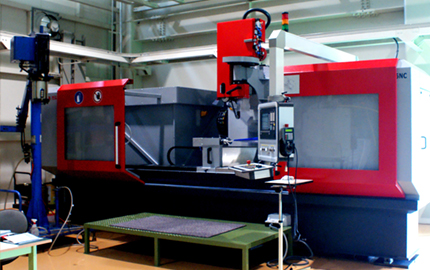

Blade center: VM-X 1300

High-precision large machining center to meet stringent customer requirements.

|

-

Blade grinder: MTS -1600

Large polishing machine to improve polishing efficiency and ensure high-precision processing.

|

-

Three-dimensional measuring machine: ACCURA-RDS

Three-dimensional measuring machine to ensure quality assurance levels that meet stringent customer requirements.

|

-

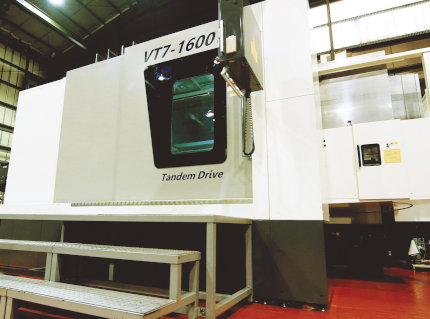

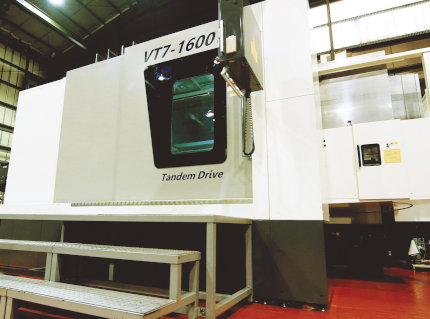

Vertical NC lathe (Tandem Drive): VT7-1600i

Max. 2000 φ enables the fabrication of large machine parts.

|

-

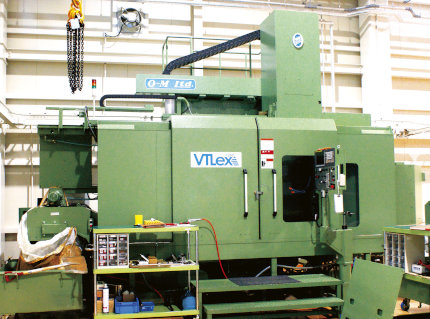

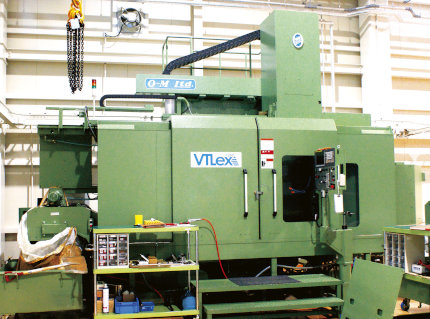

Vertical NC Lathe: VTLex 1250

Constant high-quality machining using a high-precision vertical NC lathe.

|